Progressive Cavity Pump Inspection System

Background:

A progressive cavity pump is a type of positive displacement pump transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned. This leads to the volumetric flow rate being proportional to the rotation rate and to low levels of shearing applied to the pumped fluid. These pumps are commonly used for fluid metering and pumping of viscous or shear-sensitive materials.

A progressive cavity pump can also act as a motor when fluid is pumped through the interior. This method is commonly used in oil well drilling. Mud motor (Mud Pump or Drilling Motor) refers to a Progressive Cavity Positive Displacement Pump placed in the Drill string to provide additional power to the bit while drilling. The PCPD Pump uses Drilling Fluid (commonly referred to as Drilling Mud) to create eccentric motion in the power section of the motor which is transferred as concentric power to the drill bit (well). The Mud Motor uses different rotor and stator configurations to provide optimum performance for the desired drilling operation, typically increasing the number of lobes and length of power assembly for greater horsepower.

The Problem:

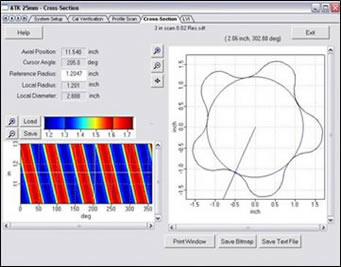

There is a fine balance required for the fit between the external surface of the metallic rotor and the internal elastomer surface of the stator. During research and development, as well as the manufacturing process, it is important to accurately measure the dimensions of both components. The stator is particularly difficult to measure using conventional methods, due to its helical geometry and the black compliant surface of the elastomer.

The Solution:

inspection of progressive cavity pump stators. Based on our BEMIS™ technology, the sensors provide extended range capability that is required to operate over a wide range of stator sizes. This system is now in commercial use for the manufacture of oil field mud pumps. The tool can also be employed for the inspection of stators as they are prepared for deployment in the field. LTC’s progressive cavity pump inspection system is a valuable tool for manufacturing quality control and for ensuring the safe, useful life of drill strings.